Good at structural optimization of high-precision injection molding parts, which can reduce the cost of injection mold by 50%

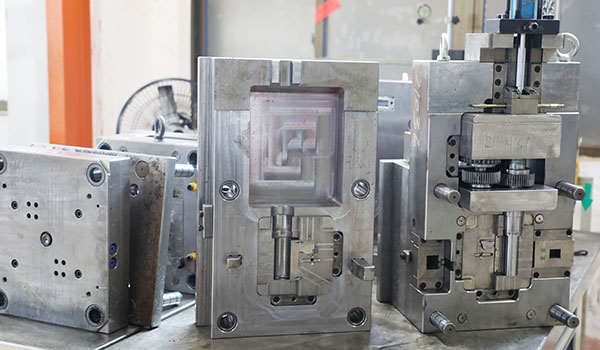

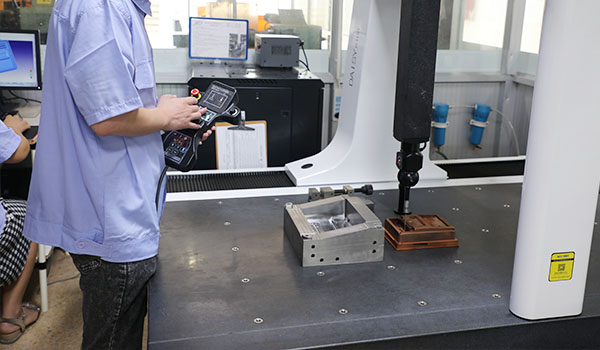

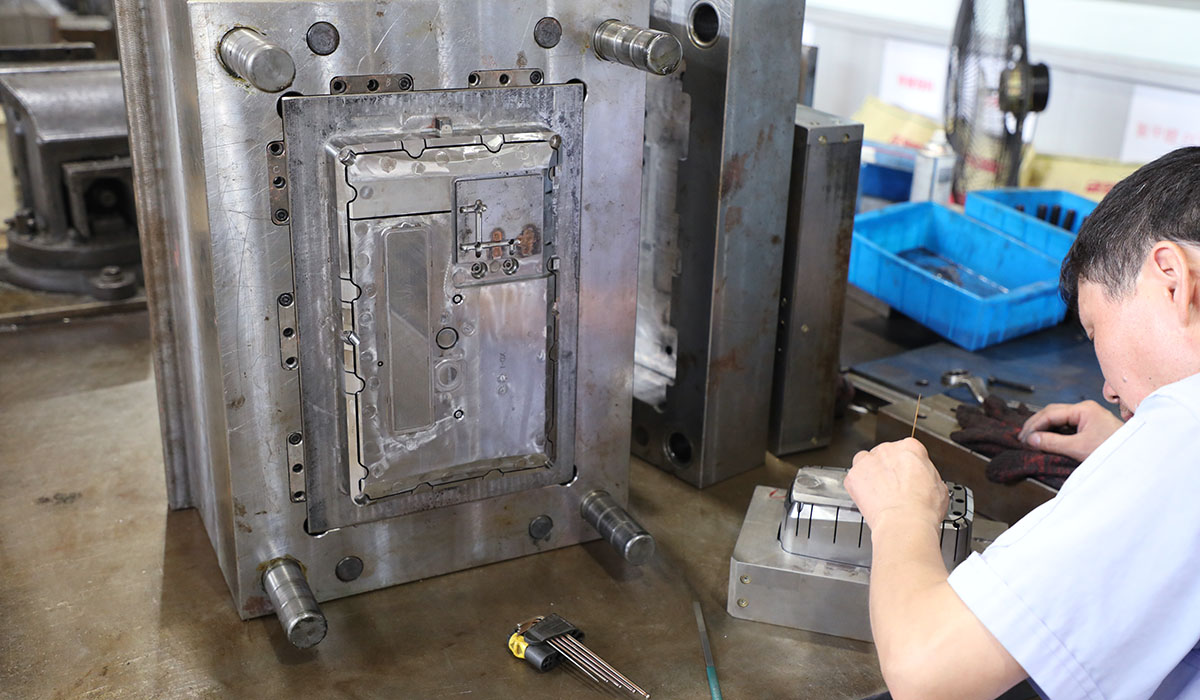

It is equipped with high-precision mold processing and testing equipment such as CNC wire cutting, full closed-loop wire walking, EDM, CNC numerical control, piercer, process grinder, bench drilling machine, turret milling machine, universal rocker milling machine, height measuring instrument and projector

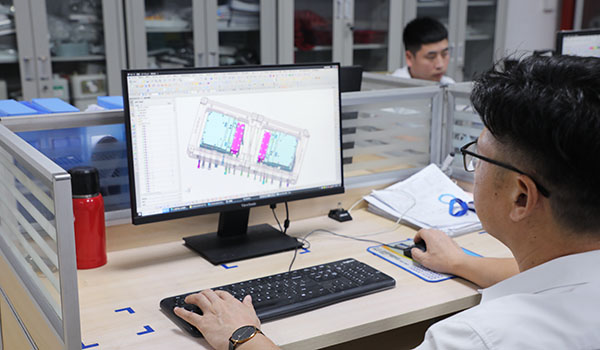

It has a comprehensive project management team with independent R & D capability, can provide technical solutions for customers or carry out synchronous development with customers, and adopts design and project management software such as Pro / E, UG, AutoCAD and Autodesk simulation Moldflow synergy;

One stop service, we have the ability to assemble the whole machine and provide complete machine service according to the requirements of customers; We can complete the semi process assembly according to the customer's requirements, assist in the design, development and assembly of relevant accessories, so that we can sell as long as the customer i…

We have automatic production line and automatic production equipment, which makes the production more efficient.

We have a 50 + R & D team specialized in engineering and technology, and have obtained dozens of patent certificates.

All processes such as mold opening, assembly, stamping, injection molding, assembly, quality inspection and packaging are completed independently in the factory, which makes customer customization easier.

It has dozens of advanced mold development equipment at home and abroad

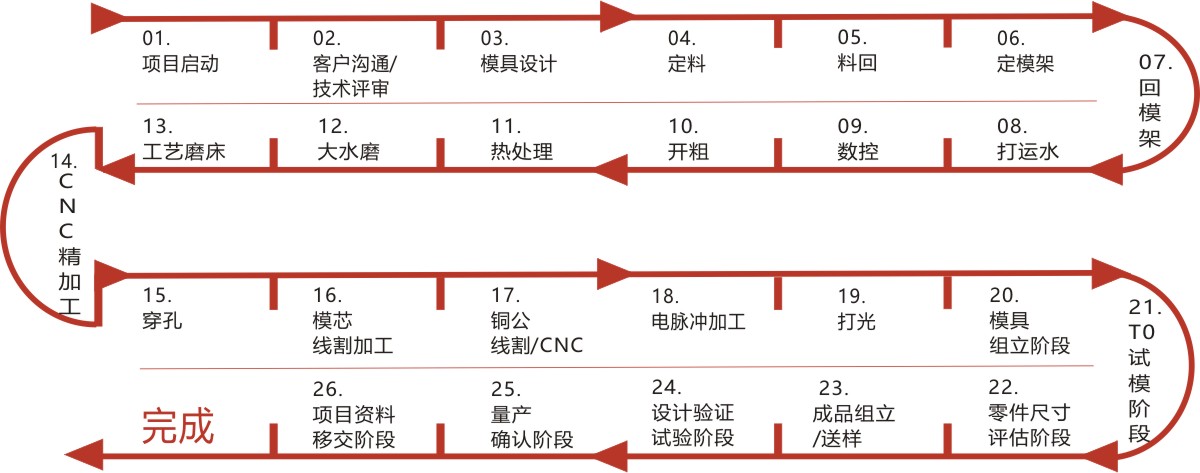

According to the difficulty of the mold, the sample delivery can be completed within 30-45 days after the general customer determines the design scheme